Core Capabilities

With core competencies in ceramic metallization, brazing, and metal-based coatings, Sigma Advanced Materials is uniquely positioned to provide integrated ceramic services that make the most out of your design.

We think strategically at the outset of a project to consider your needs and resources for the best return on investment.

We have extensive knowledge in technical ceramics such as Alumina, as well as Quartz, Sapphire, and transparent ceramics.

Metallization Services

Thick film coatings are commonly used with technical ceramics to produce thermally-superior, protected components for electronic and industrial applications. But Sigma Advanced Materials definitely does not take a common approach to application processes.

Our metallization systems involve proprietary formulations and deposit methodologies that deliver superior joining bonds and strength. We work with a wide-array of conductive materials including:

REFRACTORY METAL SYSTEMS

Molybdenum-Manganese

Tungsten

CONDUCTORS

Copper

Palladium

Silver

DIELECTRIC COATINGS

Active Braze Alloys

Inconel

Glass

Polymers

Brazing

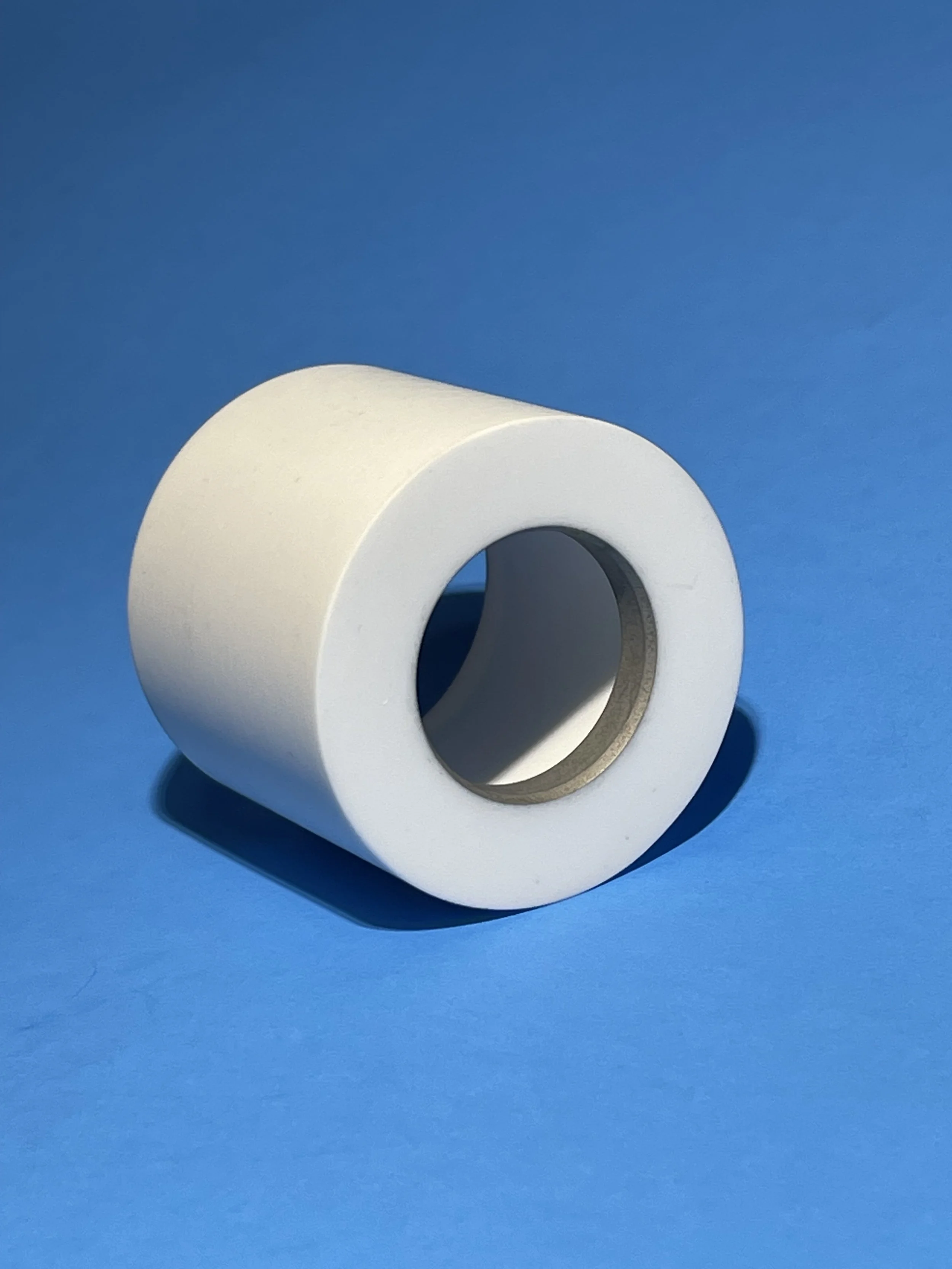

Technical ceramics and glasses may be joined with metal sub-components through the process of brazing. Using metal-based alloys, brazing creates a hermetic seal between the metal and ceramic, enabling the creation of critical technical assemblies. These may be employed in a variety of ways thanks to their strength, corrosion and wear resistance, electrical and thermal resistance, and biocompatible applicability.

Sigma Advanced Materials employs both Hydrogen and Vacuum Brazing systems, depending upon the effort required for wettability. We work with a wide spectrum of standard and exotic metal sub-components, including:

Niobium

Kovar

Copper

Stainless Steel

Invar

Titanium

Inconel

Our use of active brazing alloy (ABAs) is equally broad, with metals such as:

Nickel

Silver

Gold

Palladium

Copper

Zirconium

Value-Added Services

One of the most challenging tasks for any project manager is sourcing all of the components needed for a project. That’s where Sigma Advanced comes in. Deep relationships within the advanced material community offer us a unique opportunity to call upon our colleagues for additional services or consultative guidance when needed.

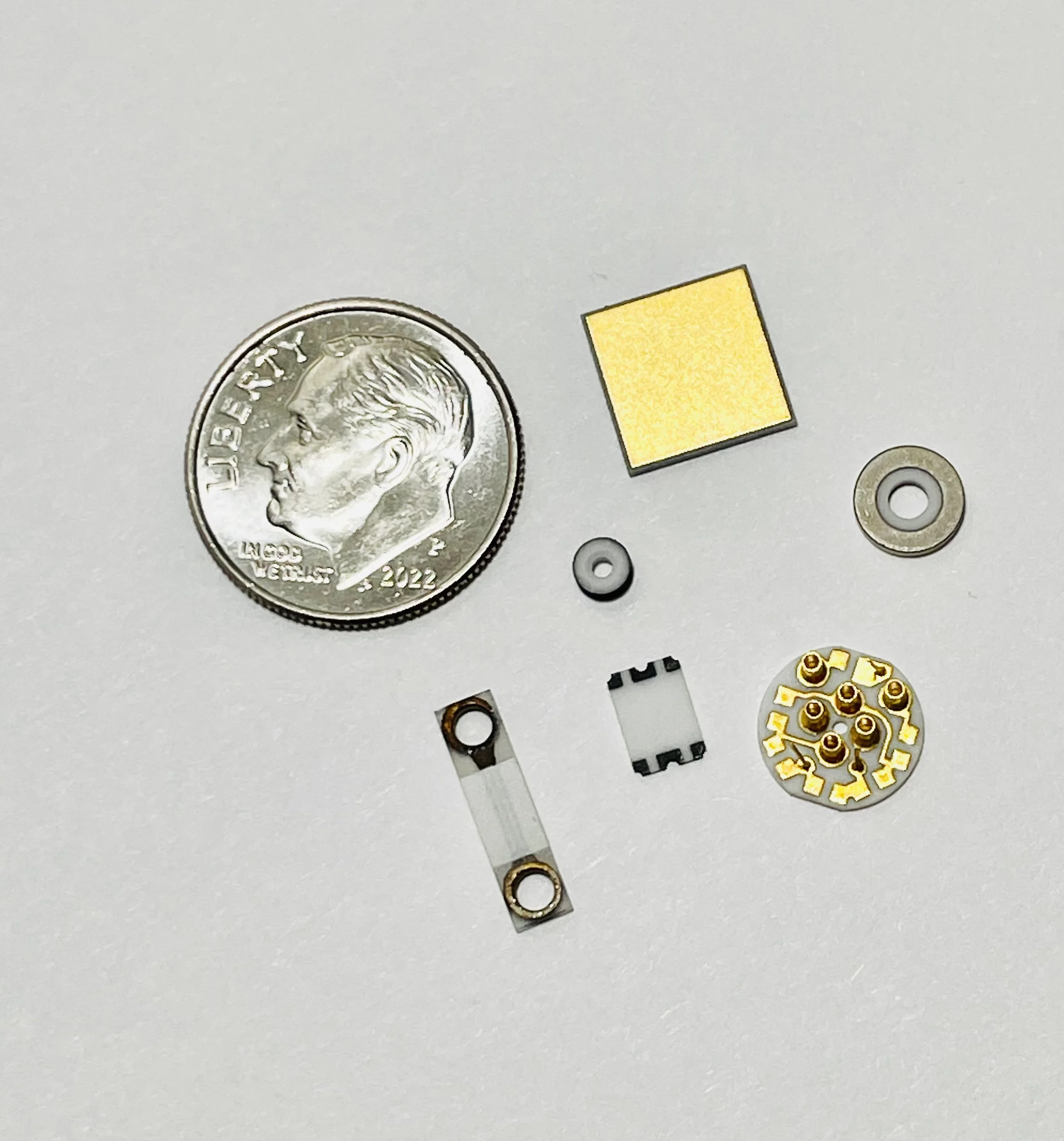

Our ability to multi-source allows us to create an integrative solution that turns your design from vision to realization in one single order rather than managing a host of disjointed and unrelated suppliers. Through our impressive network of top-tier, US-based supplier partners, we seek out the raw and finished good materials needed to complete your design.

The full BOM is managed through a single quote and invoice, making your buying experience faster, easier, and with far less paperwork to juggle. We are able to quote most projects part-complete – from ceramics and braze alloy components to full assembly kits. Our goal is always to finding the best quality, delivery time, and price for materials to provide you the highest possible value for your project. Our sourcing process involves procuring quotes from as many as four partners for a single component. We have a deep network of trusted partners and suppliers throughout the United States.

Technical Ceramic Substrates

Metal-Based Pins, Rings, Wire, and Similar Components

Machining / Grinding Services

Plating and Sintering Services

Outside Testing Services

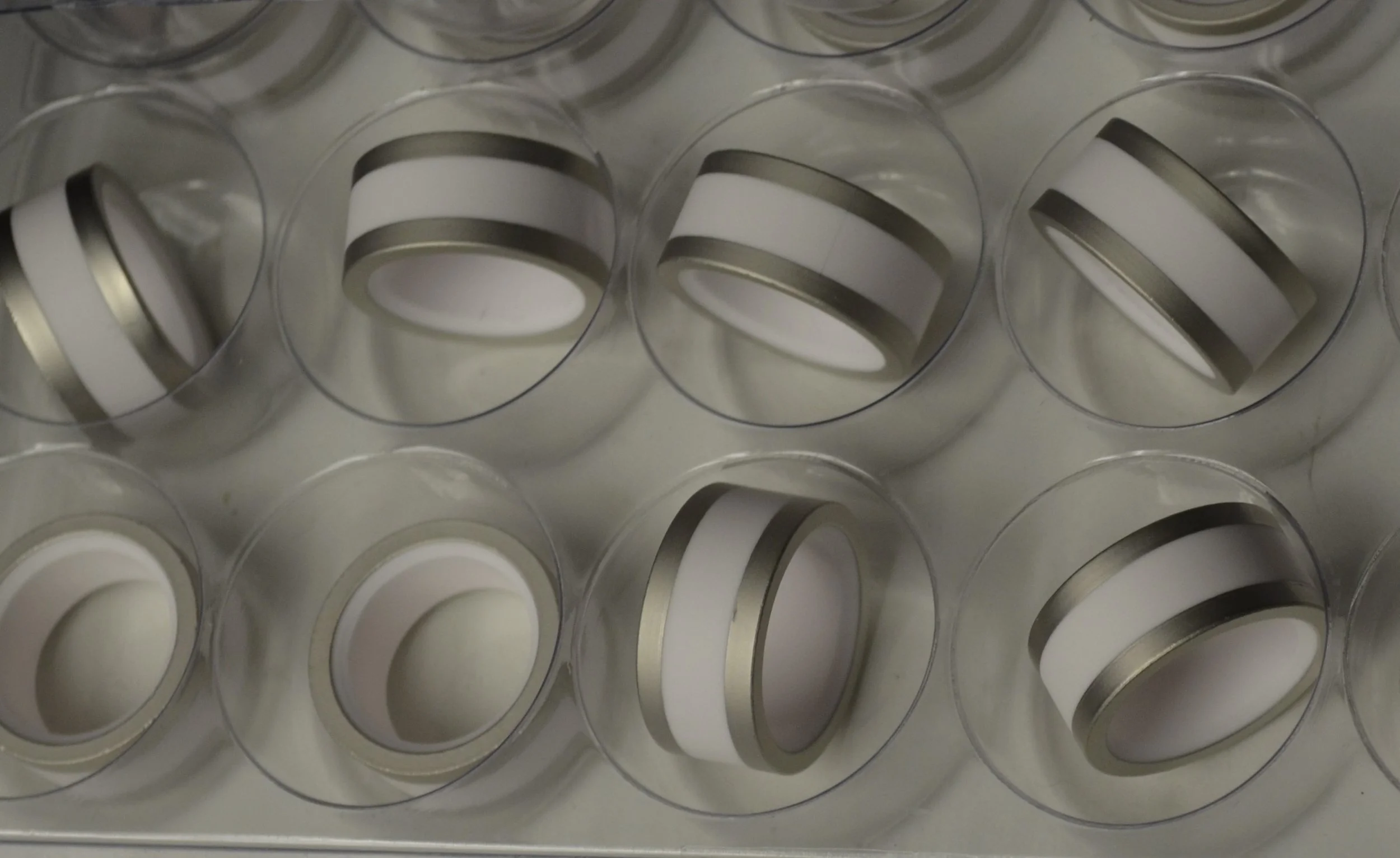

Thermoform Trays

Self-Supplied Materials

BYOC Terms:

Customer-sourced materials will be processed at the customer's own risk. Sigma Advanced Materials will charge for services rendered as contracted regardless of damage related to inherently flawed material (eg. Cracked, chipped, out-of-spec sizing, inherent flaws, stains, poor color, or other defects). NOTE THAT INHERENT FLAWS ARE OFTEN NOT VISIBLE UNTIL AFTER HIGH TEMPERATURE TREATMENT. Damage incurred to Sigma Advanced Materials equipment as a result of poor material will be charged to the customer.

Sigma Advanced Materials recommends purchasing components through reputable commercial suppliers that are We maintain relationships with numerous US-based suppliers, and can assist with guiding your selection as well as critical design choices. Sigma Advanced Materials aligns itself with suppliers that provide high-quality materials derived from ethical sources.

Looking for BYOC (Bring Your Own Components)? Our clients are absolutely encouraged to source their own certified bare components and share them with us for functional finishing and joining. Our unique agile approach allows us to flow our operational and functional steps in a bespoke manner to meet our clients’ needs.

When sending parts to us for services, we recommend partnering with an established manufacturer that stands behind their materials with certification and proof of origin. Want to order and manage your own development process but not sure which suppliers you can trust? Sigma Advanced Materials can recommend a great partner in the United States to provide exactly what you need.